French Polishing

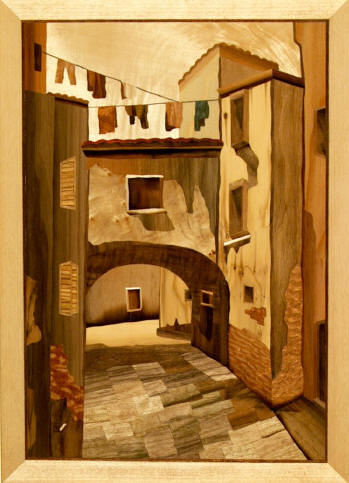

Some time ago we discovered the work of Zoltán Vargay from Hungary. Impressed by the brightness of the colours, a question from the webmaster discovered that Zoltán uses a shellac polish in a way not unlike French polishing and he was persuaded to describe his methods for us.

(English is not Zoltán's first language so I have made a few changes to his original text and added a few comments for clarity. However I am certain Zoltán's English is far better than my Hungarian! - ed)

French polish solution preparation

4% w/w solution of extra white shellac powder in denaturated alcohol (methylated spirit). The powder can be dissolved in the alcohol within 24 hours at room temperature, shaking occasionally.

Preparing the Polishing Ball

We have to use three materials for ball:

- Flax linen (outer cover)

- Wool (middle)

- Cotton ball (inside)

Polishing Steps

After sanding and before polishing the picture has to be coated with paraffin oil (thin coating) and to have a rest for 24 hours.

Moisten the inside of the cotton ball with the shellac solution (it's done this way, rather than dipping the ball into the solution, so that the solution flows outwards and any tiny paticles get retained - ed). Be careful with the wetting step (if the ball is too wet a thin layer cannot be achieved on the marquetry and the excess shellac solution will lift the earlier shellac layer).

The picture is first filled with a very thin coat of shellac. The polishing ball can be moved from line to line (horizontal and then vertical directions). Do not move the ball back on the same line (see the second diagram). The coating process can be repated when the surface is dry (if the ball not extremly wet the process can be repeated immediately after finishing a coating in the other direction.

After 10-15 coatings a break is necessary. (The old master craftsman said: a break is necessary to smoke a cigarette, today to have a cup of tea).

These processes have to be repeated until the suitable shellac coating can be achieved.

Be careful with the coating process - every time you put on a new layer the surface must be dry (if not the shellac solution takes up the earlier layer).

Between use the ball can be put in a closed bottle to keep it moist. If the ball is too dry, put a few drop of shellac solution into the inside cotton ball.

The quality of polishing and the colour of the picture is better if one or two times we put some paraffin oil drop on the picture (one small drop for every 200 square centimeter) and then continue polishing process. The shellac solution the paraffin oil over the surface. (I believe this is done to stop the polishing ball - or 'rubber' - from sticking and produces a higher gloss - ed)

The polishing can be continued until the necessary finish is achieved - the picture and marquetry maker determine the necessary coating. Sometimes the matt and sometimes the brilliant gloss surface is preferable.

Do not hurry with the polishing!

If something goes wrong and the surface of the picture appears striped, wait untill the surface is absolutely dry, then sand with very fine sandpaper and restart the polishing.

Practice makes perfect !!

The Critical Points

- Purity of the shellac

- Polishing temperature (room temperature above 20°C)

- Very thin coating in every step

- Patience

My thanks to Zoltán for taking the time to write up his method and prepare the diagrams for us. - Quentin